|

|

|

|

|

|||||||||||||||||||

|

|||||||||||||||||||||||

Amcan Coil Coating was established in year 2000 to produce Pre-painted Steel Sheet in coil form with the technology collaboration with Yodogawa Steel Works Ltd of Japan and a Swedish paint company, Beckers on our Multi-Purpose Color Coating Line.

Fully backed up by the Japanese Technology in steel and Becker’s expertise in paint, Amcan Color Coating Line is capable of applying a wide variety and range of colors on high quality (GL) 55% Al-Zn Alloy coated steel coils as the standard material to meet our customers’ requirement.

With an integrated quality control system in place at every stage of our production, the line system is able to offer a wide range of coated products like the Double Coat Double Bake for Regular Polyster.

Our Premium Series of Amcan Durafresh and Amcan Durafluor is another superior paint system offering higher durability and protection against common problem in tropical climates.

All those systems are able to cater the requirements and standards of our customers in both the domestic and overseas markets. |

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

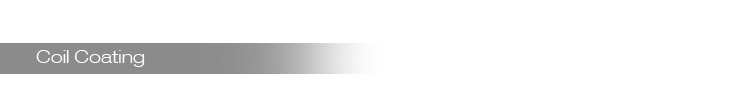

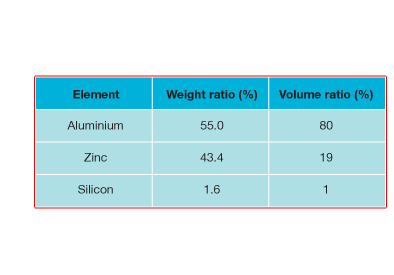

GL is a corrosion-resistant, alloy coated steel produced by a continuous hot dip process. The alloy coating comprises about 55% aluminum, 43.4% zinc and 1.6% silicon. This coating provide a balance between the superior corrosion resistant quality of aluminum and the sacrificial galvanic protection ability of zinc. Thus, quality performance of GL extends the range of applications more essentially. |

|||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

|||||||||||||||||||||||

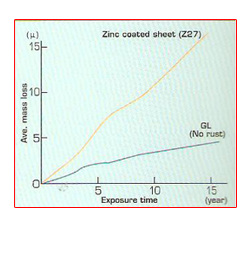

The alloy coating of GL provides the optimum composition of aluminum and zinc for corrosion resistance and galvanic protection. Atmospheric exposure test results confirm that corrosion resistance of GL is quite good, compared with zinc-coated steel sheet.

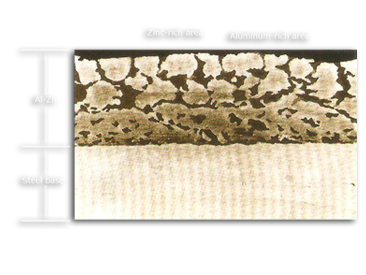

As shown in Photo-1 above, the alloy coating has Al-rich phase and Zn-rich phase formed like net structure.

Accordingly, it provides galvanic protection to bare steel by a similar mechanism to zinc coatings, and also corrosion resistance of aluminum prevents the steel from rusting in good balance with zinc function. On the other hand, aluminum 100% coating itself cannot prevent the steel from rusting on its cut end section or if it has a scratch which reveals the bare steel.

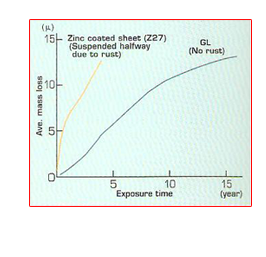

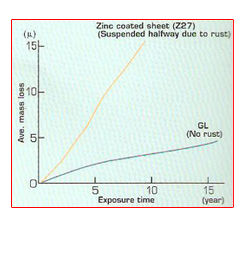

Atmospheric exposure test

Atmospheric exposure tests have been carried out in USA for a long time. Each site is, for example, severe marine, industrial or rural, and the results are as per Figure 1 to 3.

Each figure shows the relation between exposure time and corrosion rate in each area. The result of the tests indicates that GL sheet exhibits no evidence of rust on its flat portion under the condition where zinc-coated sheet (z27) has red rust on its whole surface.

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

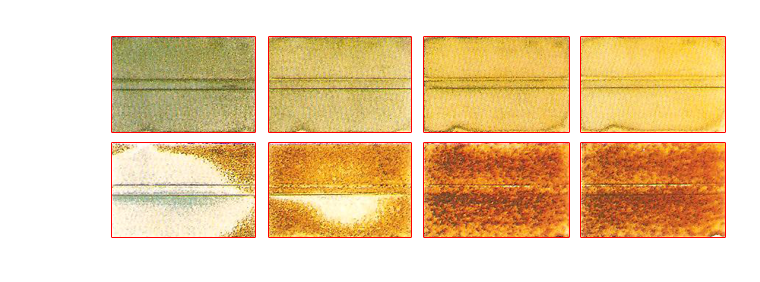

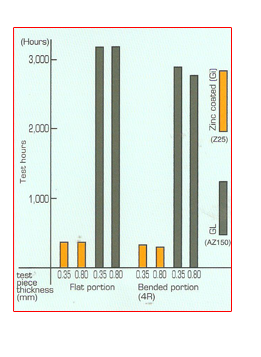

Salt water spray test

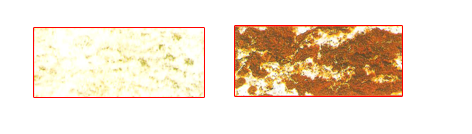

The salt water spray test was carried out to the flat portion of GL in accordance with JIS Z2371 (35 C, 5 %SOLUTION).The results is as per Photo-2.

Photo 2 shows that GL has no red rust while GL has red rust entirely.

Figure-4 is the results of salt water spray in both portion flat and bende (4R) between zinc coated sheet and GL sheet. It shows that GL has about 10 times of durability in corrosion resistance to zinc coated. |

|

|

|||||||||||||||||||||

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

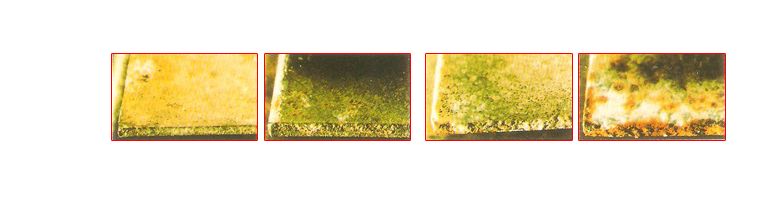

Sulfurous acid gas test

A sulfurous acid gas test was carried out to examine the resistant quality of GL against exhausted gas from cars and factories which leads to acid rain issue now brought up at various parts of the world.

As the results, GL has proven to be 6 to 8 times more durable than zinc-coated steel sheet. The test results for 800 hours is as per Photo -3. |

|||||||||||||||||||||||

|

|

||||||||||||||||||||||

Humidity test

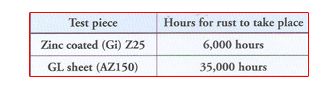

Humidity resistance is an important factor to be tested for building materials. In the humidity test, time for rust to begin to take place is as per Table shows. |

|||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

|||||||||||||||||||||||

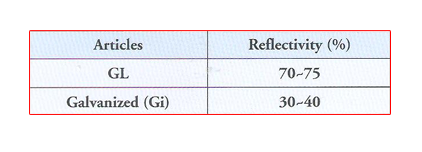

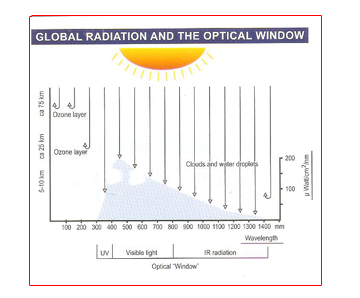

GL sheet is the most suitable as roofing materials for building to be designed for energy saving and also heat reflectors for toasters and cooking ovens, since the surface of GL is very fine and shiny enough to reflect heat and sunshine. |

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||

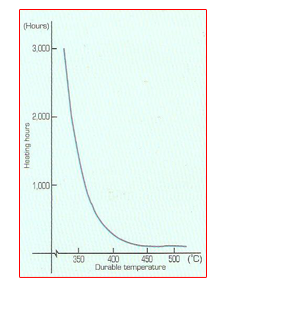

Heat resistance

Aluminum accounts for 80 % (in volume ratio) of the A1-Zn alloy coating and consequently the GL sheets have heat oxidation resistance close to aluminum coated sheet.

GL sheets can be employed for long time under the temperature as high as 300 to 350 C.

The Figure -5 showns a relation between the durable temperature and heating hours for your reference. This figure shows that GL sheets have heat oxidation resistance under the condition of less than 300 C. Prior to practical use, the test piece is provided for your trial application. |

|

||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

Amcan Durafresh Endless Freshness in Color

Amcan Durafresh Pre painted GL steel is coated with a paint system that was formulated using super durable binder and high performance pigments for long term weathering, color vibrancy and freshness. This premium pre- painted GL system provides excellent corrosion protection and surpasses performance of any other conventional pre-painted steel products. Amcan Durafresh has very good resistance against tropical dirt staining, prolonging the freshness of color on buildings.

Amcan Durafluor Timeless Protection in Color

Amcan Durafluor Pre painted GL steel is developed to provide outstanding weathering properties of color durability, resistance to chalking peeling amd excellent chemical resistnce. The superior coating system comprises minimum 70% PVDF binder (Hylar 5000 or Kynar 500) and comes in wide range of colors. Amcan Durafluor offers performance of long term protection for buildings any environment, even in the harshest weathering conditions in all climates for a period of more than 20 years.

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

The exposure carried out at Bohus Malmon, Sweden is one of the world’s harshest environments. But the tests do not end there. The weathering test facilities at Florida, Arizona, South Africa and Asia ensure that our coatings are capable of withstanding a wide range of extreme environment. The Pre-painted panels are rigorously tested not only in the laboratory but also in the extreme environmental weathering tests globally.The exposure carried out at Bohus Malmon, Sweden is one of the world’s harshest environments. But the tests do not end there. The weathering test facilities at Florida, Arizona, South Africa and Asia ensure that our coatings are capable of withstanding a wide range of extreme environment. The Pre-painted panels are rigorously tested not only in the laboratory but also in the extreme environmental weathering tests globally.

|

|||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

|||||||||||||||||||||||